* Interwoven smooth spiral wires gives sling complete flexibility to conform to the contours of the load which resists cutting and abrasion to wires.

* Wide bearing surface gives you better load balance and gripping power.

* Repairability: We can repair nearly all brands of metal mesh slings.

* Each Sling stamped with serial number and capacity.

* Each sling proof tested and certified.

* Neoprene, PVC Covering, Urethane, Coverings available upon request. For maximum load protection, specify a covered sling (additional charge will appply for upgrade). The sift, smooth elastic coverings enhance the slings gentleness, safety, service life, and ease of handling. The coverings increase sling thickness by about 5/16", yet flexes to a radius as small as 2". Safe operating temperatures up to 150 Degrees Farenheit.

G35 Heavy Duty (10 gauge): Offers longest service life and is the most resistant to rough treatment. Excellent for abrasive loads, cutting action of sharp edged loads, off-center lifts.

*Most popular type, sizes and lengths shown, Contact us for additional sizes and lengths or any special mesh items you may need custom engineered to specific, unusual applications.

Wire Mesh Sling Inspection

Wire Mesh Sling Inspection

Remove sling from service if any of the following is visible:

* A broken weld or brazed joint along sling edge or at end spirals

* A broken wire in any part of the mesh

* Reduced flexibility due to distortion in the mesh

* Reduction of wire diameter of 25% due to abrasion or 15% due to corrosion

* Visible distortion greater than a 10% angle on an end fitting

* Cracked or excessively worn end fittings

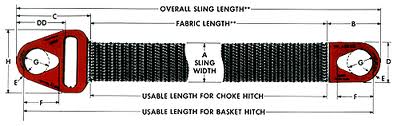

** Standard Tolerance +/- 1/2"

Type 1 Shown and priced below

Type 2 (not shown) has male handle on each end and is used exclusively for basket applications only.

Do not exceed rated capacities !

Do not exceed rated capacities !  Click here for Important Safety Warnings

Click here for Important Safety Warnings